The Importance of Acoustic Barriers in Noise Control

Acoustic barriers are essential in reducing airborne noise and insulating impact sounds. These barriers prevent sound transmission loss and act as anti-vibration pads, making them crucial for various industries. Acoustic barriers offer excellent vibration-dampening properties and can be customized to fit different surfaces, including curved and wavy structures.

Barrier products are particularly effective in environments where thermal radiation needs to be reflected, providing both sound insulation and heat resistance. They are available in sheet form, die-cut, and water-jet cut to meet precise specifications, making them adaptable for a wide range of applications.

Applications of Acoustic Barrier Products

Acoustic barriers are widely used across various industries, providing noise reduction solutions in different environments. Some common applications include:

- Automotive Industry: Used in vehicles to minimize engine noise and improve cabin comfort.

- Home Appliances: Applied in white goods such as refrigerators, dishwashers, and washing machines to reduce operational noise.

- Lift Cabins: Helps in reducing mechanical noise in elevators.

- Metal Furniture: Enhances noise reduction in workplaces and homes.

- Steel Sinks and Tubs: Reduces noise generated by impact and vibration.

- Earth-moving and Agricultural Vehicles: Used to dampen engine and operational noise.

- Machinery and Equipment: Reduces noise levels in industrial settings.

- Pipe Insulation: Prevents sound transmission through plumbing and ductwork.

Types of Acoustic Barriers

1. Polymeric Acoustic Barriers

Polymeric acoustic barriers, such as C03 (1.4mm) and C09 (2.5mm), are low-density vinyl membranes designed to improve sound insulation. These barriers are lead-free and free from unrefined aromatic oils and bitumen, making them an environmentally friendly option.

They are ideal for enhancing the soundproofing capabilities of existing panels made from metal, wood, or plastic. Additionally, they effectively overcome coincidence dip resonance in stiff, lightweight composite materials like plywood and hollow core panels.

2. Bitumen PE Foil Covered Acoustic Barriers

C022 (3mm) and C023 (5mm) barriers come with a black PE (polyethylene) face and a self-adhesive backing. These products are highly effective in preventing sound transmission loss and reducing vibrations. The PE foil surface prevents oil seepage from the bitumen-based barrier, keeping it clean and easy to handle.

3. Bitumen Aluminium Acoustic Barriers

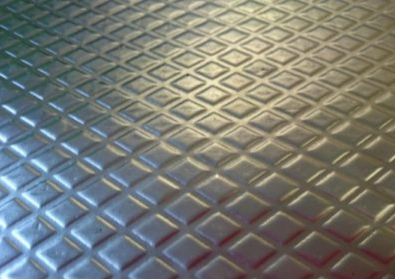

C024 is an advanced acoustic barrier with a laminated mixture of bitumen, polymers, and mineral fillers. The aluminium foil surface makes it suitable for environments exposed to heat, such as engine blocks in cars, construction vehicles, agricultural machinery, and marine applications. This barrier significantly reduces noise and enhances durability in high-temperature settings.

Benefits of Acoustic Barrier Products

Using acoustic barriers offers multiple advantages across different sectors. Some key benefits include:

- Superior Noise Reduction: Effectively minimizes airborne noise and impact sounds.

- Vibration Dampening: Reduces vibrations in mechanical systems and industrial machinery.

- Thermal Insulation: Some acoustic barriers provide heat-reflective properties, making them suitable for high-temperature environments.

- Versatility: Available in different materials and thicknesses, suitable for diverse applications.

- Customizability: Can be cut and shaped to fit specific requirements.

- Environmentally Friendly: Many acoustic barriers are made without harmful substances like lead and bitumen.

- Durability: Designed to withstand harsh conditions, including moisture, heat, and continuous vibrations.

How Acoustic Barriers Enhance Soundproofing

Acoustic barriers work by preventing sound waves from passing through walls, floors, and ceilings. Unlike acoustic foam, which absorbs sound waves, barriers act as a shield, reflecting and blocking noise.

For best results, acoustic barriers can be combined with other soundproofing materials, such as acoustic foams and damping sheets, to create multi-layered sound insulation solutions. This combination helps in controlling both airborne and impact noise, ensuring a quieter and more comfortable environment.

Installation and Maintenance Tips

- Proper Placement: Install acoustic barriers at noise sources or on surfaces prone to vibration.

- Adhesion: Use self-adhesive backing or strong adhesives for secure attachment.

- Regular Inspection: Check for wear and tear, especially in high-traffic or industrial areas.

- Cleaning: Keep barriers clean to maintain effectiveness, avoiding harsh chemicals that may degrade the material.

Read also: Why BPM Software Is a Game-Changer for Scaling Businesses

Conclusion

Acoustic barriers play a crucial role in noise control across various industries. These barrier products not only reduce sound transmission but also enhance vibration dampening and thermal insulation. Whether in automotive, industrial, or household applications, acoustic barriers provide effective solutions for noise reduction.

For customized acoustic solutions, combining barriers with other materials like acoustic foams can significantly improve soundproofing performance. Investing in high-quality acoustic barriers ensures better noise control, comfort, and efficiency in any environment.

If you’re looking for reliable acoustic barrier products, explore the available options and choose the best fit for your specific needs.